Fire rated steel profiles

A vast system of fire rated steel profiles

A unified look from a single supplier to cover all the requirements on the work site

Fixed windows, glazed walls

Single and double doors with asymmetric divisions

Complex glazed compositions with doors, side lights and top lights

Automatic, motorized, sliding single or double doors

Quotation on the fly?

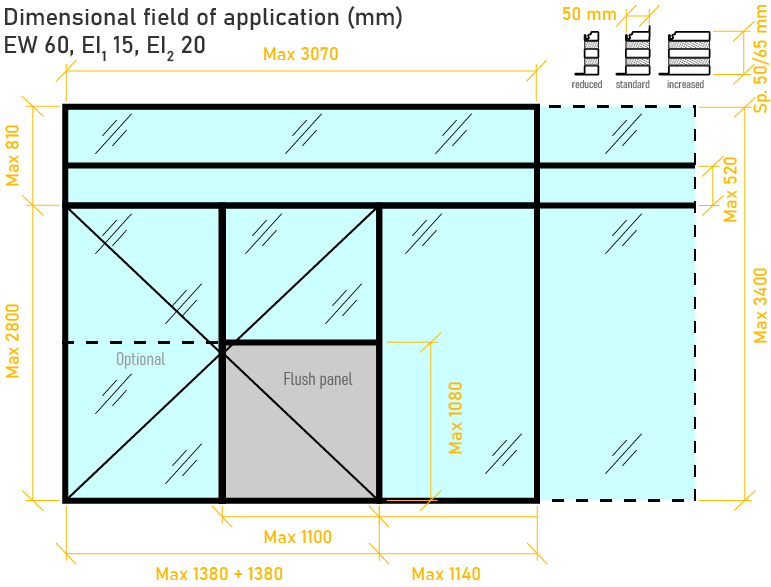

Field of application

The welded corner joints give these fire rated steel profiles the incomparable strength allowing them to be certified as:

- for internal and external use with CE marking

- non fire rated multipurpose (multi) or flamestopping (E/EW)

- fire resistant (EI) and/or smoke proof (Sa/S200)

- bullet proof (FB)

- blast / explosion resistant (ExR)

- burglar proof (Rc)

Multi

Fire

Smoke

Air

Wind

Water

Acoustic

Thermal

Exit

Burglar

Bullet

Heavy duty

Finger

Motorized

Additional technical characteristics

Developed to meet high safety and durability requirements these steel profiles are tested for sound insulation, fire and smoke resistance, bullet resistance, burglar resistance, thermal transmittance (U value), water tightness, resistance to wind load and air permeability.

– Multipurpose

– CE marking EN 16034, EN 14351-1

– Fire rated (fire resistant) EN 1634-1, EN 13501-2

– Smoke proof EN 1634-3, EN 13501-2

– Air permeability EN 12207, EN 1026

– Acoustic insulation (dB) EN 14759, EN ISO 717

– Water permeability EN 1027

– Resistant to wind load EN 12210, EN 12211

– Thermal transmittance EN 10077

– Emergency exits EN 179, EN 1125

– Bullet proof EN 1522, EN 1523

– Burglar resistant EN 1627, EN 1628, EN 1629

– Good for heavy duty application in industrial or commercial environments EN 1191

The system is certified internationally and also available with the North American UL standard.

Gallery of completed projects

Steel, a material without equals

Unlike other building materials, steel offers unsurpassed stability and durability. Even with very small dimensions, constructions made from steel profiles can handle very wide spans.

Steel is also a durable material that resists long-term wear and external impact; excellent features for industrial and commercial applications with heavy duty usage, typically required for installation in hospitals, hotels, shopping centres and offices.

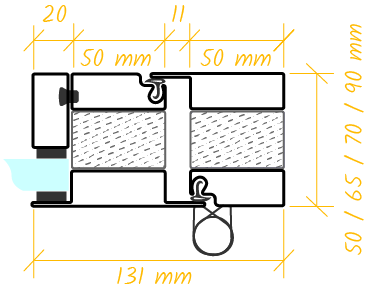

Fire resistance classes and technical data

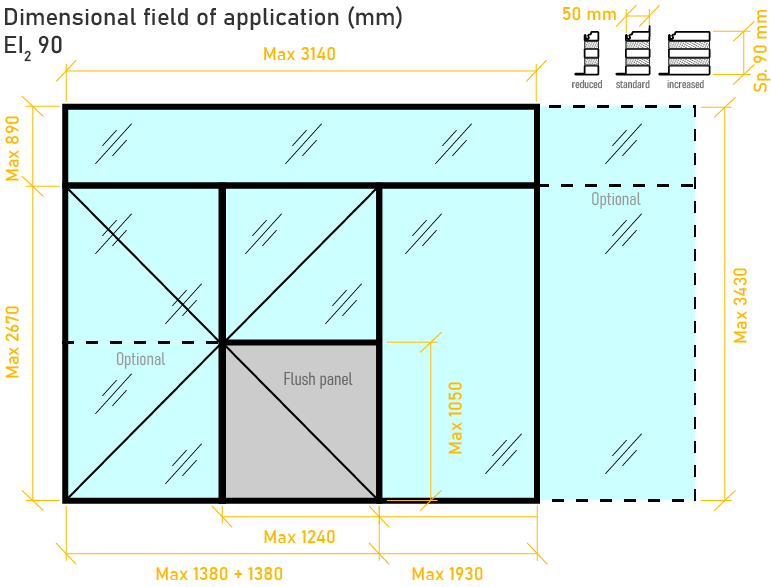

Fire rated glazed steel profiles EI2 90, internal/external (CE marking)

| Internal | External* | |

|---|---|---|

| Glass | Contraflam | Climaplus |

| Glass th. | 40 mm | 58mm |

| Glass / m2 | 82 kg | 97 kg |

| Profile th. | 90 mm | 90 mm |

| U W/m2 K | 3,30 | 1,10 |

| Acoustics | 43 dB | 43 dB |

| Burglar | RC4** | RC4** |

| Bullet proof | FB6** | FB6** |

- (*) CE marked according to EN 16034, EN 14351-1

- (**) up to the indicated value (special version)

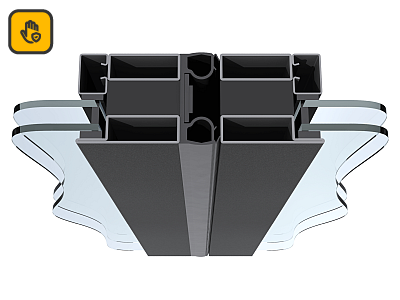

- finger trap gasket (children)

- min. glazed area 250 x 250 mm

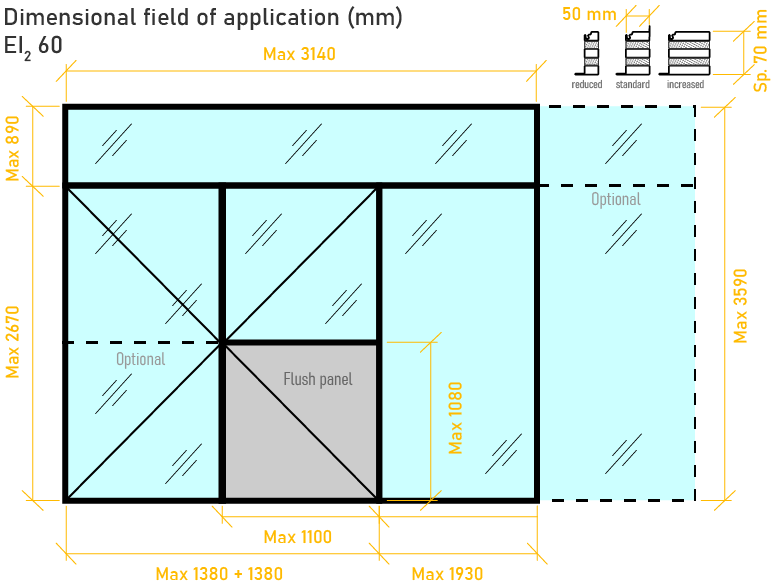

Fire rated glazed steel profiles EI2 60, internal/external (CE marking)

| Internal | External* | |

|---|---|---|

| Glass | Contraflam | Climaplus |

| Glass th. | 27 mm | 47 mm |

| Glass / m2 | 59 kg | 74 kg |

| Profile th. | 70 mm | 70 mm |

| U W/m2 K | 3,90 | 1,30 |

| Acoustics | 40 dB | 42 dB |

| Burglar | RC4** | RC4** |

| Bullet proof | FB6** | FB6** |

- (*) CE marked according to EN 16034, EN 14351-1

- (**) up to the indicated value (special version)

- finger trap gasket (children)

- min. glazed area 250 x 250 mm

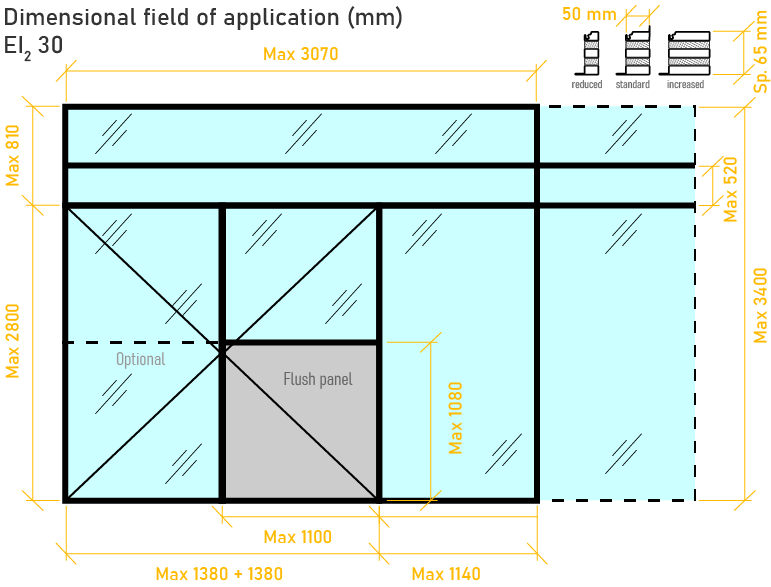

Fire rated glazed steel profiles EI2 30, internal/external (CE marking)

| Internal | External* | |

|---|---|---|

| Glass | Contraflam | Climaplus |

| Glass th. | 16 mm | 36 mm |

| Glass / m2 | 34 kg | 49 kg |

| Profile th. | 65 mm | 65 mm |

| U W/m2 K | 4,60 | 1,50 |

| Acoustics | 36 dB | 39 dB |

| Burglar | RC4** | RC4** |

| Bullet proof | FB6** | FB6** |

- (*) CE marked according to EN 16034, EN 14351-1

- (**) up to the indicated value (special version)

- finger trap gasket (children)

- min. glazed area 250 x 250 mm

Flame stopping glazed steel profiles EW 60, internal/external (CE marking)

| Internal | External* | |

|---|---|---|

| Glass | Pyroswiss | Lite |

| Glass th. | 6 mm | 34 mm |

| Glass / m2 | 15 kg | 46 kg |

| Profile th. | 50 mm | 65 mm |

| U W/m2 K | N/A | 1,5 |

| Acoustics | 36 dB | 38 dB |

| Burglar | RC4** | RC4** |

| Bullet proof | FB6** | FB6** |

- (*) CE marked according to EN 16034, EN 14351-1

- (**) up to the indicated value (special version)

- finger trap gasket (children)

- min. glazed area 250 x 250 mm

Work in progress… contact us for more information on the fly.

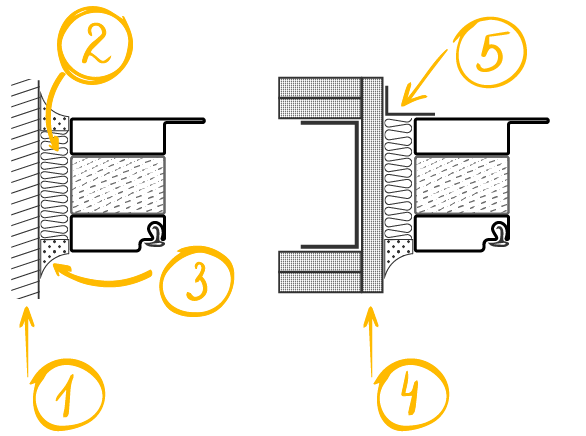

Installation onto different wall types

(1) – The most used installation type is on high-density walls such as masonry, concrete blocks, reinforced concrete and bricks. The profile system is also tested and certified for installation on walls made from prefabricated panels of various materials such as plasterboard walls (4).

(2) – Most of the wall openings are not perfectly straight, perpendicular to the frame or level and plumb. In such cases, a 10-15mm strip of rock wool can be inserted to compensate for any gaps between window frame and wall. Externally, for aesthetic reasons, small gaps between the wall and the frame can be closed with fireproof silicone (3) or with an additional steel profile (5) which in turn can be covered with plaster, mortar or other finishing material.

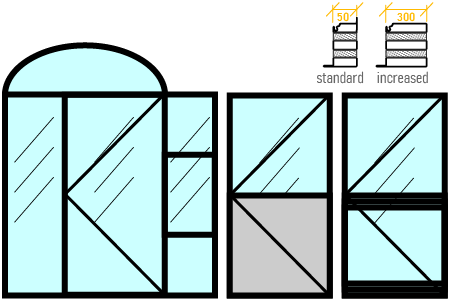

Top lights, side lights, flush panels, protection plates and kick plates

The system allows for a wide range of compositions covering all application cases. Rectangular or arched top lights are available as either one single full-length glazing or divided by an upright which covers the height. Side panels, on the other hand, are available in single full-height glazings or divided with one or more transoms in order to gain width.

To offer additional protection of the glazed system especially in heavy duty applications (supermarkets, hotels, offices, airports), the optional transoms at handle height (protective plate) and the bottom profile (kick plate) can be increased in width up to 300 mm and the glazed infills may be completely replaced by flush steel panels.

Welded frames for longevity

Our profiles are not assembled by gluing or riveting, but are welded into complete frames with seams that give strength to the construction. The welding of the profiles is a key process in the production of a steel profile frame and requires knowledge, patience and precision. Performed with care and passion it makes the product last for a long time.

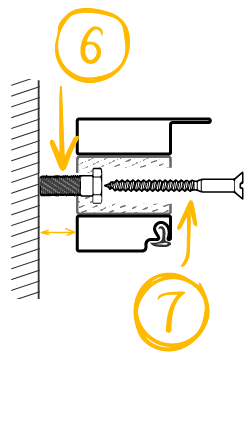

Easy prefixing and positioning

At the fixing points, the steel profiles are equipped with a thread to house the innovative “Adjufix” prefixing and positioning system (6) designed to facilitate the work of the installer. With a hexagonal key the installer can adjust the horizontal and vertical position and temporarily fix the frame in the wall opening.

On checking the perpendicularity and the gaps (between frame and wall and between frame and door leaf) the screws (7) are inserted in the central hole of the Adjufix system which acts as a seat for the final fixing.

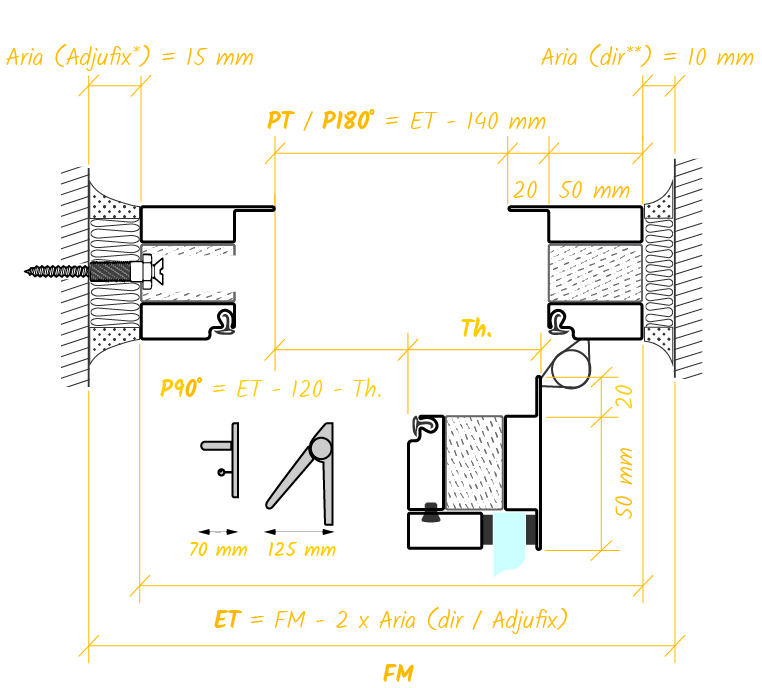

Net passage for glazed single leaf doors in width

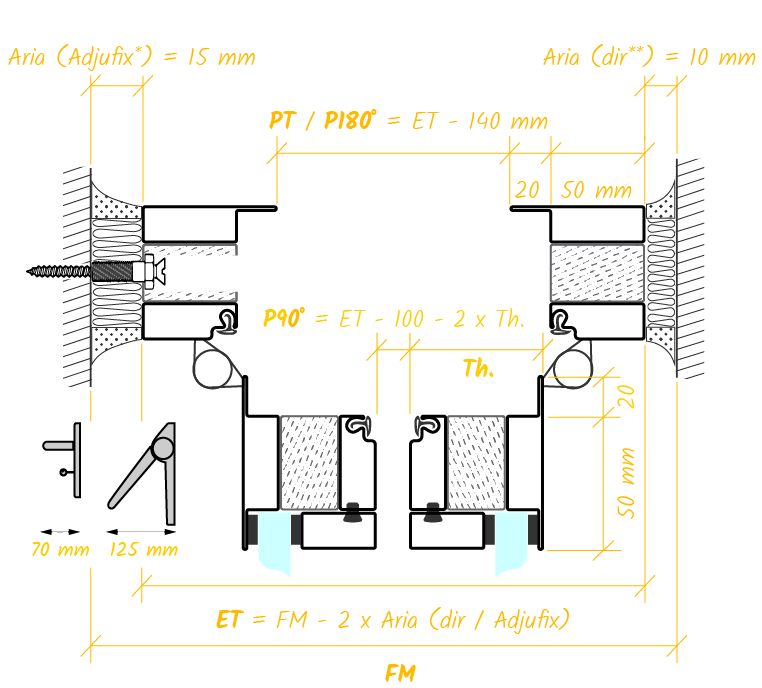

Net passage for glazed double leaf doors in width

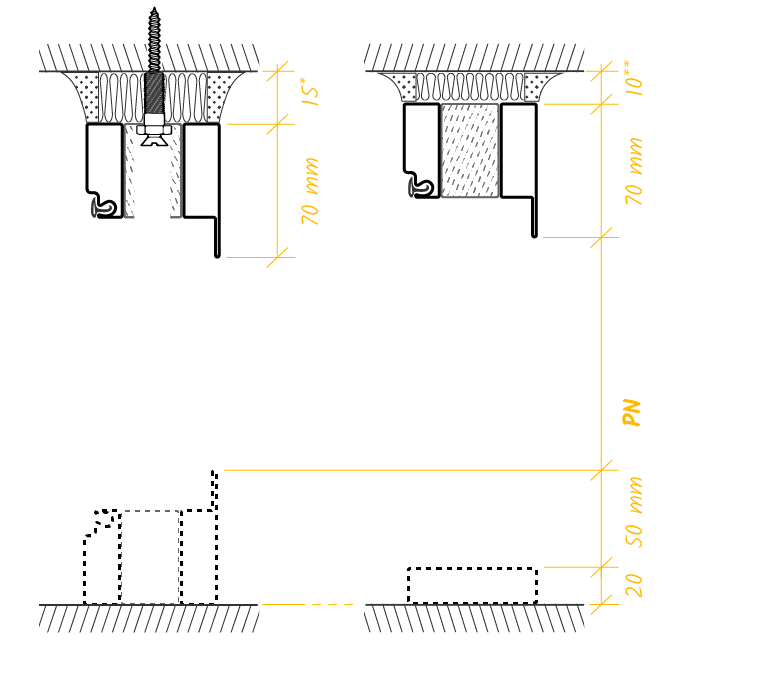

Net passage for single and double glazed doors in height

Net passage of the fire rated steel profile

The Adjufix * fixing system is supplied as standard. It can, on request, be omitted to gain 10 mm (Aria (dir) **) of passage.

The external frame dimension (ET) actually supplied is narrower than the wall opening (FM) measured on site (ordering size) as it provides for air on both sides for installation convenience.

The frame passage (PT) / passage with the leaf open at 180° (P180 °) may vary from the drawing in the case when increased or reduced profiles (other than the standard width of 50 mm) are used..

For the net passage with the leaf open at 90° (P90°) it is necessary to take the thickness of the profile (th. – 50, 65, 70, 90 mm) into account. This depends on the fire resistance class as well as the overall dimensions of the handle or panic exit device.

A fixed threshold or a fourth lower frame is available as an extra option. In this case these must be taken into account for the net passage in height (PN) between the upper profile rebate and the finished floor level / fourth frame / fixed threshold.

A detailed and specific technical drawing is provided for each order which illustrates the composition of the system and shows the exact passage dimensions.

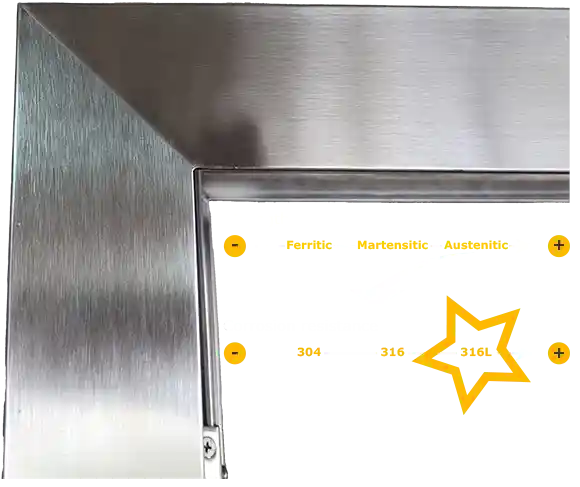

Material quality of the fire rated steel profile

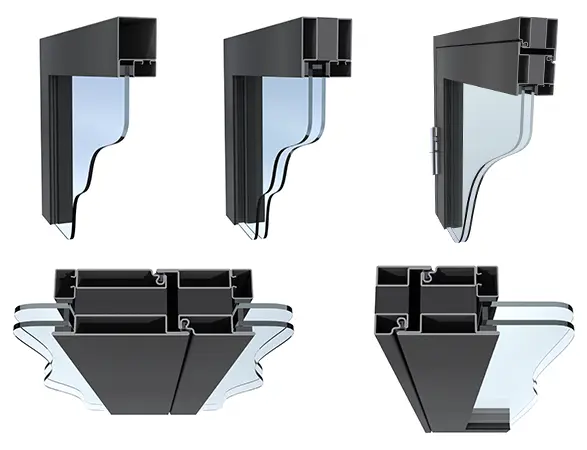

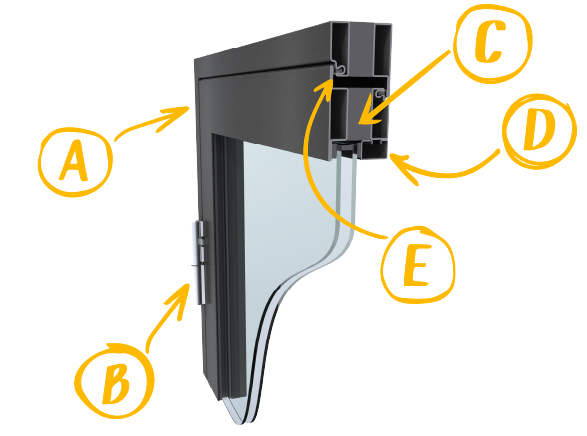

(A) – The frame and / or door profile with fixed width of 50 mm and sheet thickness of 1,5 mm is available in the following material qualities:

- painted carbon steel

- painted galvanized steel

- stainless steel inox AISI 316L painted or brushed

The profile is insulated with fire proof material (C) and is equipped with a groove for the rubber gasket (E).

Depending on the height of the frame, 3 or 4 two-winged height-adjustable hinges (B) are supplied per leaf in the same simil-RAL color as the profile. The glazing beads (D) come in the same simil-RAL color as the profile and offer a hidden fixing mechanism. Its thickness varies according to the thickness of the glass, ensuring its positioning is flush with the supporting profile.

Arched doors and fixed windows

Not only can the frame for fixed glazings be arched but so can the leaf itself, thanks to the wide range of fire certificates available.

The steel profile system is suitable for both the classical look for renovations of historic buildings and the modern minimalist look for new buildings.

Finishing of the fire rated steel profile

The fire rated steel profiles (and the welded hinges) are painted, as a standard finishing, with polyester powders with UV protection in colors from the RAL range. Most of the RAL colors are included in the price, special finishes such as metallic RALs are excluded and calculated extra.

A unified look for all fire resistance classes

The width of the profile and the glazing bead are identical for all fire classes, i.e. 50 mm (profile) and 20 mm (glazing bead) respectively in order to achieve a unified look (Multi, EW 60, EW90, EI1 15, EI2 20, EI2 30, EI2 60, EI2 90 and UL 120). The thickness of the profile, therefore, varies from 50 to 90 mm depending on the fire resistance class of the desired solution (for details see here).

Laminated fire rated glass

The steel profile system is shipped with laminated glass with moisture and pressure resistant edge sealing for extended durability. Laminated glass refers to two or more layers of tempered glass which are bonded together under heat and pressure using an environmentally friendly, transparent and UV-stable alkaline silicate which reacts in the event of fire. This intumescent interlayer expands as an opaque foam and provides the required fire resisting (E) and heat insulating (I) properties. In case of exterior applications the laminated glass is enhanced with an additional chamber forming an insulated glass unit (IGU) which provides even better insulation values.

Stainless steel AISI 316L – highest corrosion resistance

The 300 steel grades series are a popular choice for a wide variety of applications. The formulas of 304, 316 and 316L steel are austenitic, a term that classifies the crystalline structure of the metal and is responsible for the right mix of strength, weldability and corrosion resistance.

304 stainless steel is the most common stainless formula in consumer applications. With chromium and nickel alloys, 304 resists many corrosion attacks.

316 stainless steel also includes molybdenum which makes it much more resistant to corrosion.

The steel grade AISI 316L (also known as DIN 1.4401, ASTM A193, EN 1.4401) which is used for our stainless steel profiles has a much lower carbon content which gives it even better corrosion resistance than pure 316. 316L also does not require post welding heat treatment (PWHT).

Finger trap gasket

The special finger trap gasket (rubber sealing) protects against accidents involving fingers or hands being crushed on the hinge side of the door, a position of the door in which the doors exerts great force. Typically this type of gasket is used for applications in schools, nursing homes and nurseries.

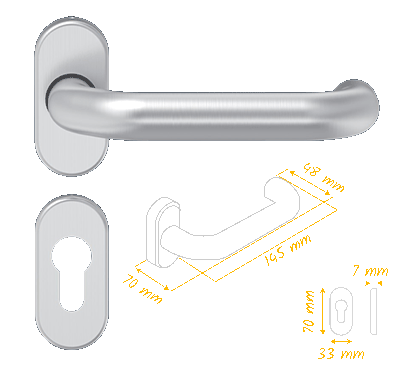

Standard accessories for fire rated steel profiles

Glazed doors are equipped with all the accessories needed to make them functional in their field of application and thus complying with the respective standards according to which they are certified. The accessories come from well-known manufacturers and the quality level chosen corresponds to the best balance between price and durability over time.

Handles

Security handle with escutcheon (rosetta) in stainless steel

Eco Schulte D116 OVR

Door closers for single leaf doors

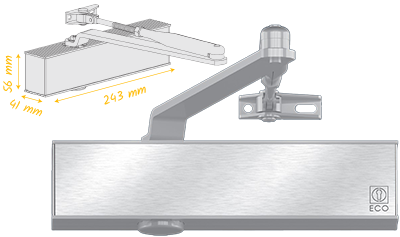

Overhead door closer with carrier arm

Eco Schulte TS-20

- installation onto hinge and hinge opposed side (to be communicated at order time)

- fully reversible for right and left handed doors

- closing force 2-5

- latching and closing speed continuously adjustable

- silver color

- tested according to EN 1154 and CE marked

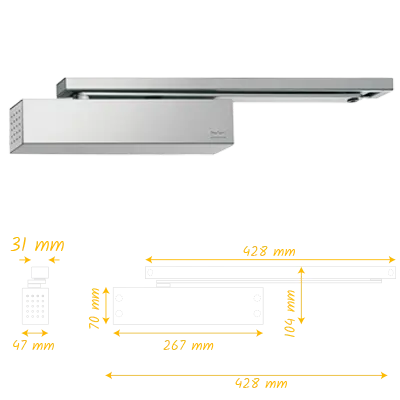

Door closers for double leaf doors and mixed projects composed of single and double leaf doors

Overhead door closer with slide channel

Dorma TS91

- installation onto hinge and hinge opposed side (to be communicated at order time)

- fully reversible for right and left handed doors

- closing force 2-4

- latching and closing speed continuously adjustable

- silver color

- tested according to EN 1154 and CE marked

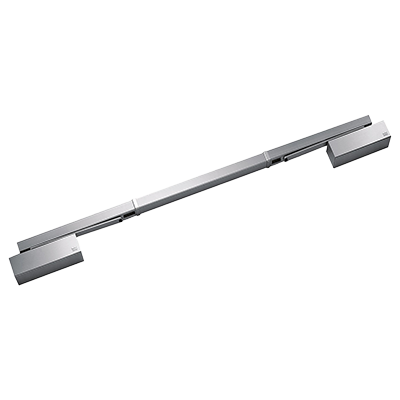

Closing regulator for double leaf doors

System of two overhead door closers with slide channel and central closing regulator

Dorma TS91 GSR

- includes 2x TS91 and 1x central closing regulator GSR

- installation onto hinge and hinge opposed side (to be communicated at order time)

- fully reversible for right and left handed doors

- closing force 2-4

- latching and closing speed continuously adjustable

- silver color

- tested according to EN 1154 and CE marked

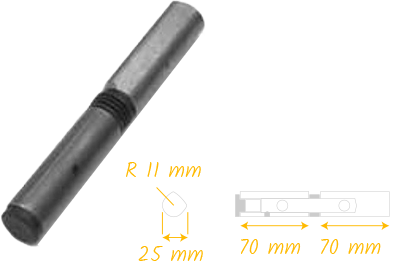

Hinges

2-winged tear drop hinge

- in galvanized steel

- adjustable in height

- welded to the frame and the leaf

- double sphere steel pin

- includes adjustment pin, fixing pin, cap and black bellows

- painted in the same simil RAL color as the frame

- doors are equipped with either 3 or 4 hinges

Packaging

Fire rated steel profiles and their respective glazings are packaged and loaded onto single-use, no-return steel crates, protected with sponge-flic and tightly fastened with polypropylene plastic straps.

Corners on all sides are shielded by cardboard strips and protected with a final wrapping of transparent stretch foil to allow for verification of the integrity of all goods on arrival.

Do you want to know more about doors and windows and their specific terms?